Daimler Truck North America (DTNA) is working with its transport provider Salem Carriers to deliver inbound parts on electric trucks in the US Carolinas.

Salem Carriers transports parts between DTNA’s manufacturing sites, supply chain hubs and supplier locations across the two states, and is using DTNA’s Freightliner eCascadia trucks on daily inbound routes.

Those operations are supported by a partnership with fleet electrification supplier Electrada on the development, operation and maintenance of the necessary charging infrastructure. The partnership is also backed by Daimler Truck Financial Services (DTFS) to provide charging-as-a-service (CaaS) with a fixed and predictable monthly rate.

“Introducing battery electric vehicles to our operations was a new initiative,” said Dennis Giff, general manager at Salem Carriers. “The DTFS/Electrada approach was unified, aligned with our operating needs, and set the stage to scale future electric vehicle integration into our services.”

With the Caas set up Salem can charge its trucks at its Statesville depot in North Carolina and en route at the Duke Energy/Electrada mobility microgrid in Mount Holly in North Carolina, adjacent to DTNA’s eastern US manufacturing plant.

“This programme with DTFS, Salem and Electrada reinforces DTNA’s commitment to decarbonisation throughout the supply chain by seamlessly using Daimler vehicle and energy solutions available to all logistics enterprises today,” said Jeff Allen, senior vice-president of operations and specialty vehicles at DTNA.

Decarbonisation drive

The efforts made to decarbonise inbound logistics in the Carolinas are the latest in a list of sustainability projects DTNA has initiated over the last. year. Last November the truckmaker introduced four eCascadia trucks in the north-east of the US. The trucks are used to move production and aftermarket parts from various supplier locations in the Pacific northwest to DTNA’s consolidation centre in Portland, Oregon. From there they are shipped to DTNA’s North American manufacturing plants and aftermarket parts distribution centres. The etrucks can be charged at Electric Island, the etruck charging site opened in 2021 in Portland, which was designed to accelerate the development, testing and deployment of zero-emission commercial vehicles.

“By integrating electric trucks into our inbound logistics network, we aim to reduce our environmental impact and contribute to a more sustainable future that goes beyond truck development and manufacturing,” said Allen.

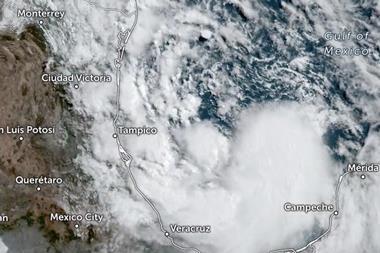

Following that, in January this year DTNA’s division in Mexico delivered the first of two eCascadias manufactured in Portland to Transportes Esteban. The trucks are being used in day-to-day plant operations at Daimler Truck Mexico’s manufacturing plant in Santiago. The plant is also the official location of the second Electric Island commercial vehicle charging facility, specifically designed to support electric charging of heavy-duty trucks.

DTNA said the Mexican facility was equipped with a Detroit eFill charger offering a charging capacity of up to 120kW and capable of charging up to 80% of the eCascadia’s battery capacity in 220 minutes. According to the truckmaker, Detroit eFill chargers work with management software for intelligent charging, optimising energy consumption and integrating vehicle information, stations and the charging process through a telematics platform.

DTNA manufacturing locations in North and South Carolina

North Carolina

Cleveland Truck Manufacturing Plant (Freightliner Trucks)

Gastonia Components and Logistics

Thomas Built Buses Manufacturing Plant

Mount Holly Truck Manufacturing Plant

South Carolina

Freightliner Custom Chassis Corporation Manufacturing Plant

DTNA is also now involved in a battery manufacturing joint venture with Paccar, Cummins’ battery subsidiary Accelera and EVE Energy called Amplify Cell Technologies, which is building a 21-GWh factory in Marshall County, Mississippi, due to begin production in 2027. The aim of the collaboration is to advance battery cells for commercial and industrial applications in North America.

DTNA’s Portland manufacturing plant makes the Freightliner eCascadia and eM2 and has achieved CO2-neutral production by reducing energy consumption and offsetting on-site emissions. DTNA said it plans to achieve CO2-neutral production at all remaining truck manufacturing plants by 2025.

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)

No comments yet