In its recently published 2022 Impact Report, Tesla reveals that its supply chain is responsible for between 30-50% of the greenhouse gas (GHG) emissions produced over the total lifecycle of one of its vehicles. It also explains in detail what it is doing to better measure and tackle Scope 3 emissions – those produced by activities outside of its immediate control.

The electric vehicle (EV) maker recognises that it had previously undercounted supply chain emissions because of the complexity of the supply chain and challenges in the availability, consistency and reporting of data.

“We recognise that we can no longer assume that a missing data point should equate to zero emissions,” states Tesla in the report. “To take steps to significantly reduce our impact, we must understand the true emissions footprint of our supply chain”.

Upstream emissions

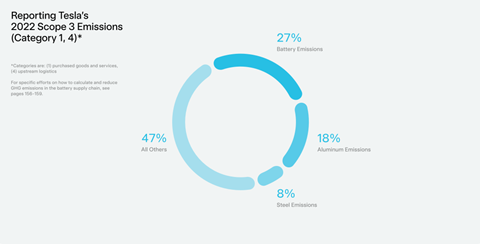

In the report Tesla outlines that supply chain emissions from the production of its EVs was approximately four tons more than a comparable vehicle powered by an internal combustion engine (ICE), and that was mostly related to the battery. The battery supply chain accounts for between 25-30% of the GHG produced across Tesla’s supply chain.

The carmaker says it took two years of driving to recover that carbon loss and that around 55 tons of CO2 was eventually saved over the lifetime of an EV.

Last year, the carmaker completed its hotspot analysis of lithium and nickel supply chains, in partnership with Minviro, a consultancy that helps companies assess the impact of their raw materials sourcing. If found that the majority of emissions from the battery chain happen upstream in the mineral refining processes.

Mining and refining battery materials such as lithium, nickel and cobalt have a significant environmental impact and Tesla outlines that it is pursuing more direct sourcing to gain transparency and traceable supply chain data on which it can act locally. It also provides information to the IFC Net Zero Roadmap for Nickel and Copper Mining. According to the IFC, the world will need to increase copper and nickel production by 200-300% to reach global climate targets by 2050. However, emissions from copper and mineral production processes are expected to double by 2050 unless sourcing is decarbonised.

Independent programmes

In its report Tesla says it is also involved in initiatives set up by outside bodies to monitor the sourcing of battery materials, including the Initiative for Responsible Mining Assurance (Irma), which it joined in 2021, and undergoes independent audits, something that Tesla recommends to its suppliers.

It is also a member of the Re|Source consortium and Global Battery Alliance, and in 2022 co-published a Battery Passport for one of its nickel-based batteries.

As with a growing number of carmakers, Tesla says it is also looking at more vertical integration and regionalisation. That includes building its own lithium refinery in Corpus Christi with a process that eliminates the use of sulphuric acid and its sodium sulphate byproduct.

Reverse logistics

Tesla reports that it has also made a lot of progress with the recycling of batteries, with none going to landfill. It states that it has deployed equipment to recycle 100% of on-site generated manufacturing scrap across its manufacturing facilities (though not that it is recycling 100% yet). It is also stockpiling any materials that cannot currently be recycled for future processing.

The report also states that Tesla has developed a reverse logistics system to recover batteries from sold vehicles. In 2022 it recovered 2,300 metric tons of nickel, 300 metric tons each of cobalt and lithium, and 900 metric tons of copper.

In the first quarter of 2023 Tesla made 440,000 vehicles and delivered over 422,000.

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)

No comments yet