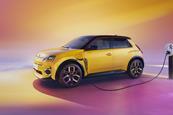

Speed to market is critical for affordable electric vehicles

As UK carmakers prepare to increase EV production and compete with cheaper Chinese imports, special care is needed to establish resilient and efficient supply chains

Delay to introduction of new rules of origin is a window of opportunity

Vendigital’s automotive specialist Sheena Patel says proposed delay on rules of origin is a chance for carmakers in the UK and European Union to strengthen the EV supply chain

Politics now the driving force in automotive supply chains

Professor John Manners-Bell explains that automotive supply chains are now developing more along political imperatives than economic ones

Automotive logistics can empower Asian manufacturers globally

DP World is building a network of technologically advanced vehicle handling terminals that Asian carmakers stand to benefit from as they export globally

Crisis in Europe could breed greater cooperation in outbound logistics

As ECG celebrates 25 years, carmakers may be more open to the idea of volume guarantees, while the EU is more supportive of harmonised truck lengths.

Watch: Thank you for joining us at Finished Vehicle Logistics North America 2022!

Christopher Ludwig closes out the 2022 Finished Vehicle Logistics North America conference, which was the most important gathering of vehicle logistics executives in more than a decade.

Watch: Welcome to a new world of finished vehicle logistics

Christopher Ludwig kicks off Finished Vehicle Logistics North America 2022, where the industry came together to address improving ETA accuracy, managing built-to-order vehicles, ensuring capacity and managing cost rises.

Watch FVL highlights: ETA, capacity, driver shortages and collaboration

Christopher Ludwig summarises key takeaways from FVL North America, where vehicle ETA, capacity and costs were major concerns, but so were finding practical ways to work together.

Russia’s invasion of Ukraine is a long-term risk for the automotive supply chain

The impacts stretch beyond inflation and corporate retreats to critical shortages upstream for semiconductor and EV supply.

On the sidelines at ALSC Global Live: the calm before the perfect storm

Christopher Ludwig introduces Automotive Logistics and Supply Chain Global Live in Detroit, as the industry meets in the midst of massive disruption and change across automotive supply chain.

On the sidelines ALSC Global Day 1 in review: logistics data, mitigating shortages and managing the chip crisis

Christopher Ludwig recounts highlights of the first day of Automotive Logistics and Supply Chain Global Live, picking out highlights and learnings from OEM, tier supplier and logistics providers at the event.

Goodbye from Detroit at Automotive Logistics and Supply Chain Global Live

It’s time for a new beginning in supply chain partnerships if the industry is to manage through current disruptions and meet the changing needs of electrification, sustainability and new technology.

On the sidelines ALSC Global end of conference wrap up: this is only the beginning

Christopher Ludwig recounts highlights of the first day of Automotive Logistics and Supply Chain Global Live, picking out highlights and learnings from OEM, tier supplier and logistics providers at the event.

Parts suppliers need to understand rules of origin

Parts suppliers in the UK need to understand a few priorities about the rules of origin by the end of this year if they are to correctly assess the tariffs that will be applied

Real-time visibility platforms keep automotive supply chains moving

The global automotive market is competitive and volatile, and manufacturers and OEMs were already under pressure thanks to new market challengers such as Tesla, and consumer preferences shifting towards electric vehicles (EVs).

Comment: It’s supply chains that are competing now

Before coronavirus, companies would assign top priority to areas such as manufacturing efficiency, process optimisation and smart sales and marketing. Not anymore. Today, in a world where even the biggest and best-organised corporations are scrambling to survive, the focus is squarely on the supply chain.

Comment: Crisis leads to change

In ordinary times, when we talk about something being viral we normally mean social media – a wildly popular video of someone falling over, or perhaps a puppy montage. In the extraordinary times that we now find ourselves, the meaning of the word has reverted back to being deadly serious. The emergence of Covid-19 (coronavirus) this year has ravaged the global population, sent entire nations into lockdown and brought business virtually to a standstill.

Comment: Slow-growth China holds more challenges for OEMs than coronavirus

Coronovirus and its sudden impact on the Chinese economy might be occupying the news headlines, but there are broader changes afoot over the longer term. After many years of enjoying high-speed growth, the automotive industry is facing its third consecutive year of shrinking vehicle sales in China. For foreign vehicle-makers operating in the country, this is a challenging situation, and while most will be planning to tough it out, some could be forced to exit the market – requiring a shift in patterns of production and logistics.

Part and parcel of the problem: why tier 1 supplier logistics will face a squeeze

As OEMs and automotive parts suppliers see their margins decline, cost pressures are going to increase on logistics operations and service providers further down the supply chain

Explaining EU vehicle emissions targets: can OEMs avoid heavy fines?

The new average fleet targets that came into force in Europe on January 1st 2020 are having big impacts on the supply chain, pushing OEMs to produce and sell more hybrids and EVs. But the rules are complex and varied by brands, volume and sales. Here we provide a summary of the key rules and terminology.

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)