Watch: Welcome to the future of North American automotive supply chains

Kicking off the on-demand content for Automotive Logistics and Supply Chain North America Live, our hosts set out the trends impacting the industry today and how they will reshape processes, service and partnerships.

Watch: A surprisingly bright outlook for North American vehicle sales and production

Despite the pandemic and supply chain disruptions, IHS-Markit is forecasting a stronger-than-anticipated rebound for the North American automotive sector, however there are many headwinds, including for production and exports out of Mexico.

Watch: The race to build a North American lithium-ion battery supply chain

Investing in regional battery supply will be critical for OEMs in North America to compete on electric vehicles, but can battery cell capacity keep up? Analyst Daniel Harrison details the evolving battery production footprint in the region.

Watch: Maintaining Mexico’s competitive edge in supply chain

OEMs in Mexico are facing logistics bottlenecks and expect more to come, which is why Nissan and providers like Jack Cooper are strengthening processes and digital tools in logistics to improve resiliency and flexibility.

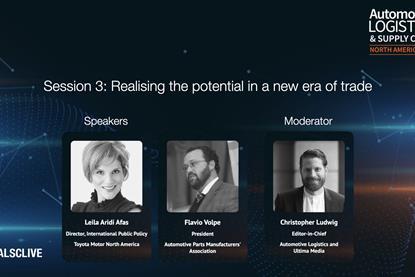

Watch: North America automotive suppliers must keep up with USMCA and changing trade policy

Policy experts from Toyota and Canada’s automotive supplier association unpick complex sourcing and compliance rules under USMCA, and look ahead to what the Biden administration could mean for automotive trade.

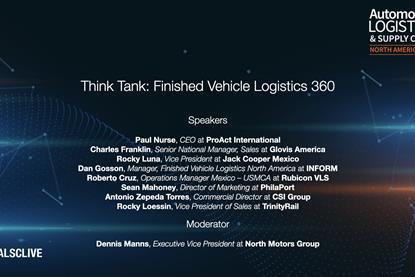

Watch Think Tank: A 360 view of finished vehicle logistics in North America

Key operators from all corners of the vehicle logistics space discuss the major trends in the sector for 2021 as part of an interactive think tank, including representatives from road, rail, ports, IT and integrated services.

Watch: Managing global supply chains in times of disruption

As the automotive industry faces logistics capacity and semiconductor shortages in the supply chain, experts from Volkswagen Group, emergency freight provider CNW and packaging specialist CHEP discuss systems and strategies to improve resilience.

Watch Think Tank: Top tips on transforming aftersales logistics in North America

In a special think tank workshop, leaders from key players in service parts and aftersales logistics discuss how the industry should respond to the current disruptions and get ready for major changes ahead.

Watch: Toyota turns to technology to redesign US vehicle logistics network

Toyota’s Rick Wishon discusses how the carmaker is using optimisation tools from software specialist Inform to engineer its outbound logistics network to maximise capacity and reduce lead times even as complexity rises.

Watch: Using digitalisation to build supply chains back better

Executives from tier one supplier Magna, 3PL DSV and automation specialist Seegrid outline how automotive manufacturers are accelerating the digitalisation of the supply chain in the wake of the Covid crisis.

Watch: Can OEMs design more flexible and predictive supply chains networks?

Logistics executives from Toyota North America and agricultural equipment manufacturer AGCO discuss their strategies, processes and technologies for advanced logistics and supply chain planning.

Watch: Capturing supply chain data and change in real time – day one in review

Our team unwraps the top themes from the first day of the event on North American automotive logistics, including managing organisational transformation and an urgent need for data transparency.

Watch: Top priorities for the North American supply chain in 2021 – intro to day two

Christopher Ludwig reveals top priorities for the region’s automotive logistics and supply chain sector at the start of day two of ALSC North America Live.

Watch: North American automotive recovery is underway, but for how long?

The North American automotive market is on pace to return to growth this year despite slow vaccine roll-outs, however there are risks in the supply chain and the longer-term economic outlook, according to Eaton’s top automotive analyst, Brandon Mason.

Watch: How Volkswagen and Kuehne + Nagel are making supply chains greener

In this virtual event, leaders from Volkswagen and Kuehne+Nagel discussed how production and supply chains can be made greener by using renewable energy in plants, switching deep-sea shipping vessels to LNG, reducing air freight and more.

Watch: Canada’s Silicon Valley of the North

Leaders from Magna, Toyota and LeddarTech discuss how Canada’s supply chain can realise its potential for innovation as the Silicon Valley of the North, thanks to the local expertise and electric vehicle initiatives like Project Arrow.

Watch Think Tank: Starting up electric vehicle supply chains

With new OEMs like Lucid about to launch electric vehicle production, supply chain experts from OEMs, suppliers, tech players and logistics companies discuss the investment, data and technology opportunities – and difficulties – that come with starting up new EV and battery supply chains.

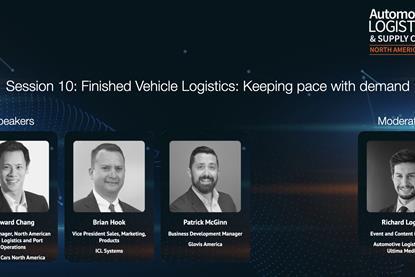

Watch: Ensuring finished vehicle logistics keeps pace with demand

Senior managers from Porsche, Glovis and ICL Systems talk about how they have been keeping dealer lots stocked as consumer demand has returned since the end of stay-at-home orders across America.

Watch: Mexico’s supply chain is ready for electric car production

With the Ford Mustang Mach-E, the first EV has started production in Mexico. Alex Katsouris from freight forwarder Europartners examines what needs to happen in the supply chain to make the country a powerhouse for EV production.

Watch: Exceptional finished vehicle logistics

If vehicle logistics providers are to keep ahead of disruption and better serve customers, they will need to improve exception management and inventory visibility across plants, yards and transport according to executives from Hyundai Glovis, Jack Cooper and Cognosos.

Watch: Rise of the robots

What can automotive logistics learn from other industries when it comes to automation and robotics? Experts from Locus Robotics, GE Appliances and i9 Sports compare notes on how robotics can help efficiency as well as those working in logistics.

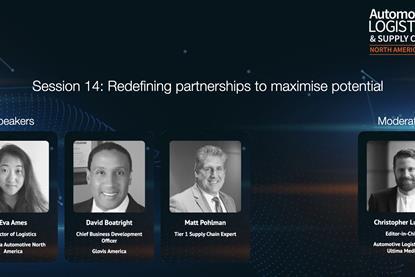

Watch: Covid could accelerate outsourcing and new partnerships in the supply chain

Experts from Mahindra, Hyundai Glovis and the tier supply chain say that the crisis highlights opportunities for new logistics services and a re-evaluation of partnerships across automotive logistics in North America and beyond.

Watch: That’s a wrap (until next time)!

At the end of a two-day journey across the supply chain in the US, Canada and Mexico, our hosts share the most urgent action points and takeaways from the event, including how logistics providers can help manufacturers recover and transform.

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)