Leaders from BMW, VW, Audi, and more gathered at ALSC Digital Strategies Europe 2024 in Munich, where experts discussed digital solutions for sustainable, resilient and co-creative supply chains. Follow our recap blog below for all the insights, including news, features and Red Sofa video interviews.

11 December

Did you miss our ALSC Digital Strategies Europe 2024 event? Well don’t worry, you can catch up on the highlights in our wrap-up video from day two.

Christopher Ludwig, chief content officer,Automotive Logistics highlighted actionable strategies, real-world use cases and tools shaping the future of automotive logistics.

Watch the full video now!

11 December

Continuing our Red Sofa series from the event, both Alexandre Lerma and Jorge Miguel Corral Díaz from Seat joined us to discuss how the OEM’s Human AI strategy and its Vortex AI software is helping enhance data quality, streamline operations and foster cross-functional collaboration.

Lerma, manager of logistics, customer driven supply chain, said the Human AI strategy is raising awareness about AI and bringing training on it to Seat’s workforce, integrating the OEM’s digital control tower to manage data quality and data governance.

Meanwhile Díaz, Seat’s senior IT specialist – AI, data & hyperautomation, said that Seat’s proprietary Vortex AI generative software acts as a tool that allows the OEM to “chat to its data”. Vortex AI allows seamless data-driven decision-making, such as comparing supplier offers, navigating regulations and analysing logistics performance.

Watch the full Red Sofa interview now

6 December

Jean-Christophe Deville, vice-president of supply chain at Toyota Motor Europe joined us on the Automotive Logistics Red Sofa at ALSC Digital Strategies Europe to discuss Toyota’s approach to digitalisation, focusing on its key initiatives of Project Velos and the Toyota Mega Hub.

Deville said that through Toyota’s mega hub and insourcing complex vehicle accessory fitting, Toyota has achieved better quality and process control. The integration of digital instructions supports team members with detailed, step-by-step guidance, ensuring safety, quality, and productivity improvements.

Watch the full Red Sofa interview now!

5 December

Our first Red Sofa interview from the event is out now!

Watch Paulina Chmielarz, digital innovation director for Industrial Operations at JLR, share key milestones and innovations driving the carmaker’s ambitious transformation across supply chain, manufacturing and procurement.

4 December

Assess the risk and pick your battles

In the final session of this year’s ALSC Digital Strategies Europe conference representatives from JLR, Daimler Truck and software service provider Celonis talked about risk-proofing supply and production.

Actions speak louder than words and they also prove the efficacy of an established risk strategy once the more salient dangers are identified, whether they relate to regulatory compliance, geopolitical crises, natural disasters or financial instability. Data transparency is important but that alone cannot help a company.

“We need to have a proper process and consequence management in place,” said Marion Gillich, head of supplier risk management at Daimler Truck. “If I know a certain KPI is dropping, then great, I have a look at it and say, yeah, okay, it’s dropping, but what do I do with that?”

Daimler Truck has adopted an octopus model to deal with supplier risk from a financial perspective amongst its suppliers and one of the arms Gillich and her team are strengthening is the assessment of supplier sustainability. For the last five years the supplier risk management team has been collecting carbon disclosure project (CDP) scores from its suppliers and creating a report that is sent to Daimler Truck management.

Now it is working on building in consequences should the CDP scores go up or down, and it is making the different risk categories more transparent. Another example of consequence management relates to whether a supplier is in an area of high risk from flooding or other climate-related disruption. “Here we’re working together with our supplier management and logistics counterparts to say, ‘hey, we saw that your supplier is in a high-risk area for flooding, can you please check are the right mitigation measures at the supplier in place’,” said Gillich.

Similarly, JLR has processes around data-fed risk detection, which Simon Inskip, director of supply chain digital and innovation at the carmaker, described as a sensing platform. “When a risk becomes an issue and it needs management get resolved, then we have processes and mechanisms stepped up to support that,” he said. “The data side of things has been a case of evolving while we’ve had to run at the same time so some of the thinking that we have now for data needs to be retrofitted back to what we’ve already done. But ultimately those learnings have forced where we need to go in the future as well.”

Inskip said that JLR had to move fast on its risk-sensing capability and is in the second year of full deployment and already the carmaker is looking for greater data granularity and substance from its platform and that means increasing the accuracy of input data. “When you know, for example, the address and the location of all your tier ones then its happy days,” said Inskip. “I get all the risks associated to that location and if there is uncertainty around that, then that uncertainty is played back in the risks that you get as well.”

That level of visibility on risk plays into the demand for end-to-end transparency in the supply chain and as a provider of the technology on which carmakers and tier suppliers depend for that transparency, Celonis is focused on how its software-as-a-service improves processes and operational excellence. That again goes back to opening silos.

“We need to provide a platform that allows for the different silos to be connected with each other so that the data that you have in the silos can be brought into context and you can actually make deductions from it,” said Julien Thomßen, global automotive and manufacturing industry lead at Celonis. However, while the technology is available, getting approval for its adoption across the board at a company is more tricky.

“It’s way harder to get that through the political side of organisations,” Thomßen acknowledged. “If you take big end-to-end processes, like the order-to-delivery process in automotive, you have the production lord, you have the sales lord, you have the logistics lord. You might convince one or two but convincing everyone at the same time is much harder.”

Thomßen’s advice was to pick your battles and identify the biggest value could be gained. “Make a point about why that technology is needed and also be humble and honest,” he said. “If a simple Power BI dashboard is sufficient, then don’t fight because it won’t get you anywhere.”

4 December

Collaboration begins at home

Bolstering the automotive supply chain for the future is not just about the latest technology, it is about culturing a collaborative mindset in a competitive landscape. This afternoon speakers from Seat, Infineon Technologies and battery maker CATL discussed how a shared vision was essential for problem solving and building a resilient supply chain strategy.

A company has to be internally aligned before it can offer value to its customers, according to CATL’s Aleksej Kruekov, general manager of overseas service for the Europe, Middle East and Africa (Emea) region. By example, Kruekov pointed to the predictive maintenance platform CATL has been running in China for several years that analyses battery and cell performance in real time and provides data on the behaviour of the cells. The data helps identify any abnormalities with which CATL can generate early warning systems. With that he said CATL was able to add value in terms of safety and reliability to the supply partnerships it has with its OEMs.

Maximising OEM satisfaction through more reliable products and services is also important to Infineon Technologies, which makes semiconductors. Providing them to a high standard depends on bridging the functional and data silos within the organisation, which is what Infineon has done according to Fuchs, bringing together sales, marketing, operations and finance step by step. The result is an increase in pace and quality. Fuchs said the aim of that internal collaboration was increasing customer satisfaction and strengthening external partnerships.

Speaking for the OEMs, Alexandre Lerma, manager of logistics and customer driven supply chain at Spanish carmaker Seat, said that working together across departments within the company has proven to improve results, as seen in the internal IT and business alliance behind the carmaker’s digitalisation strategy (read more here). That teamwork is now in the mindset at Seat and Lerma said the carmaker is seeing much better results than expected with everyone more engaged and key performance indicators up across the board driving the company forward.

That spirit of collaboration now extends beyond Seat, though Lerma admitted that there have been challenges in convincing suppliers to share data for closer supply chain integration. “It was hard to gain trust at the beginning but thanks to the early adopters they saw the win-win of sharing the data.. and that has helped us move on to other suppliers that did not want to collaborate who see the results that we are getting.”

Lerma said that the trust Seat has built with its supplier is based on sharing data and being transparent about the common benefits for all.

4 December

Toyota and Bosch on navigating change management

Now in a panel discussion, Jean-Christophe Deville, vice-president of supply chain, Toyota Motor Europe and Juliana Raidt, head of data privacy and information security, Bosch talk about the human dimension of digitalisation.

Raidt discussed the challenge of helping employees adapt to new tools and processes, stressing the need for robust change management strategies. She noted that Bosch prioritises efficiency gains and upskilling rather than workforce reductions, ensuring employees see digital transformation as an opportunity rather than a threat.

Deville highlighted the dynamic nature of partnerships, and acknowledged that the Velos project’s outcomes had deviated from initial expectations, underscoring the importance of adaptability and trust in external partnerships.

In closing, the panel underscored a shared vision: by empowering employees, embracing innovation, and remaining adaptable, automotive companies can thrive in a rapidly evolving industry.

4 December

Bosch’s approach to leadership and implementation in logistics

Juliana Raidt, head of data privacy and information security, Bosch closely followed Jean-Christophe Deville’s presentation. She spoke about Bosch’s Transport Management System (TMS) which leverages features such as paperless workflows, real-time tracking of trucks, multilingual interfaces for cross-border logistics, and automated registration and security checks.

The system is operational at 39 locations globally, with plans to expand further. This rollout process has required adapting to regional regulations, she said, demonstrating Bosch’s commitment to legal compliance and operational flexibility.

Raidt also spoke about the importance of data privacy and cybersecurity, and said it is important to collaborate early with cybersecurity experts to avoid inefficiencies during project rollouts. She said that ensuring data privacy compliance remains a cornerstone of Bosch’s strategy, particularly given varying regional regulations, and shared an example of how Bosch had to reject certain localised practices to uphold stringent privacy standards.

4 December

Leadership, strategy and implementation within production and logistics at Toyota

In his presentation, Jean-Christophe Deville, vice-president of supply chain at Toyota Motor Europe, shared the OEM’s strategy to transition from a survival mode during recent crises to a more systematic and high-performing supply chain model.

Deville talked about two initiatives the carmaker has been implementing in its digital strategy. Toyota Motor Europe has developed Velos planning software in collaboration with Inform to improve visibility and efficiency in vehicle logistics planning. The system offers real-time insights into stock levels, transportation needs, and potential bottlenecks, allowing Toyota and its partners to forecast and allocate resources more effectively. Additionally, he said Velos enables dynamic prioritisation of vehicles, moving beyond the traditional first-in-first-out method to enhance customer satisfaction.

The second initiative Deville mentioned was Toyota’s new Megahub in Czech Republic, which was inaugurated last month. He said the Megahub integrates digital instructions to streamline option-fitting processes for vehicles.

4 December

We are now breaking for lunch after which we will be back with leaders from Toyota Motor Europe and Bosch to explore the fundamental shifts needed in leadership thinking and organisations to develop a successful digital transformation journey, from digitalising truck transport and vehicle logistics, and adapting change management across stakeholders.

Before the conference closes, we will also hear from experts from Alexandre Lerma, manager of logistics, customer driven supply chain from SEAT, Birgit Fuchs, vice president of supply chain automotive from Infineon Technologies and Aleksej Kruekov, general manager overseas service EMEA from CATL on key steps that can be taken to bring about effective collaboration and talk about how trust can be built, visions can be aligned, and automation can be widespread.

Stay tuned!

4 December

Investing in supply chain insights to gain competitive advantages

Just before lunch, we welcomed John Torres, lead senior data scientist, Mercedes-Benz; Eric Ramatchandirane, supply chain management IT solutions manager, Autoliv; and Leonid Yanshin, sales executive, supply chain, InterSystems to the stage. In a world of increasing complexity, the automotive leaders from Mercedes-Benz, Autoliv and InterSystems shared their expertise on harnessing data to enhance supply chains.

The panel explored the power of governance, collaboration and advanced analytics to unlock efficiency and agility in a competitive market.

Torres highlighted how fragmented systems hinder data quality and decision-making. Mercedes-Benz’s strategy involves consolidating legacy systems and connecting data lakes with a focus on governance. Similarly, Ramatchandirane shared how Autoliv’s multi-region operations face challenges with harmonising data from over 60 sites using different ERP systems.

Yanshin emphasised the role of modern tools in breaking silos, advocating for connective layers that allow seamless data exchange across diverse systems while ensuring data validation and enrichment.

A robust data strategy offers significant rewards. Yanshin compared an optimised supply chain to possessing a “crystal ball and magic wand,” enabling foresight and automation.

Torres underscored the strategic advantage of connecting data across procurement, logistics, and marketing. This end-to-end visibility enables faster, more informed decisions, crucial in today’s volatile environment.

The panel agreed that the journey to a data-driven supply chain requires more collaboration, and said that organisations must align leadership with actionable strategies and foster a culture that values transparency and innovation.

4 December

Balancing agility with governance

Trre Wong, senior manager, global supply chain digitalisation, Kautex Textron joined Schaeffler Technologies’ Hilgerloh on stage to talk about balancing agility with adherence to governance structures. Hilgerloh noted that a well-defined digitalisation strategy provides a “target picture” that helps manage expectations and prevents redundancies. Wong shared an example of collaborative innovation hubs at Kautex Textron, where cross-functional teams work together to tackle shared challenges, such as calculating carbon footprints across the supply chain.

A recurring theme was the importance of addressing knowledge gaps between IT and business units. Both panellists acknowledged the challenges of aligning priorities, with Wong explaining that businesses often demand immediate solutions while IT focuses on long-term governance.

To foster alignment, Schaeffler shifted governance responsibility to business teams, empowering them to collaborate on digital strategies. Meanwhile, Kautex Textron implemented talent development programmes to embed digital literacy across the organisation, allowing departments to co-create innovative solutions that address their specific needs.

The panel concluded with a call to action: digitalisation must be treated as a business-wide initiative. Both Wong and Hilgerloh underscored the need for collaborative environments that connect experts in technology with those who understand operational nuances.

4 December

Bridging digital gaps in logistics: Schaeffler’s supply chain overhaul

Tammo Hilgerloh, head of supply chain digitalisation at supplier Schaeffler Technologies, took to the stage this morning to discuss how the company reshaped its logistics to boost efficiency, transparency and sustainability by addressing inefficiencies, enhancing data quality and adopting a modular approach.

With over four million annual deliveries and a nine-figure transportation spend, Schaeffler recognised the need for systemic change to streamline operations and meet strategic objectives such as cost reduction, emissions tracking and lead-time optimisation.

He said that Schaeffler’s transportation logistics were fragmented, relying on over 30 disconnected IT systems, manual processes and outdated tools. Hilgerloh likened this fragmented system to a “Frankenstein’s monster”—functional but far from optimal. The realisation prompted the development of a cohesive digital strategy that aligned with the company’s overarching business goals.

Hilgerloh emphasised starting with the business strategy to ensure digital initiatives addressed core objectives. This involved standardising processes, achieving data transparency by transitioning from manual data exchanges like Excel and emails to API and EDI integrations, enhancing data quality using machine learning, and simulation and optimisation through predictive models to manage risks and evaluate business impacts.

4 December

We are breaking into our first networking break for the day for delegates to discuss the takeaways from the sessions and other trends in the digital automotive logistics landscape.

We will continue with some keynotes and panels from Tammo Hilgerloh, head of supply chain digitalisation from Schaeffler Technologies and Trre Wong from Kautex Textron, who joined us yesterday on stage as well, to talk about developing digital solutions for strategic supply chain objectives.

We will also hear from John Torres, lead senior data scientist at Mercedes-Benz AG, Eric Ramatchandirane, supply chain management IT solutions manager at Autoliv and Leonid Yanshin, sales executive, supply chain at InterSystems on how digital leaders are turning supply chain data into a competitive advantage, whether in anticipating and responding to potential disruption, or in providing suppliers and customers the most accurate, actionable information.

Stay tuned!

4 December

Addressing automotive supply chain blind spots

The panel discussion “Seeing through automotive supply chain blind spots” brought together experts from JLR, Volkswagen Group and Brose Group to explore challenges and strategies for improving transparency and efficiency in the automotive supply chain.

Agnieszka Kubiak, senior vice president of logistics at Brose Group, emphasised the difficulty of unifying legacy systems and overcoming organisational silos. “Our blind spots often arise from inconsistent data and process harmonisation,” she noted, adding that initiatives like Brose’s SAP realignment aim to address these gaps.

Building on insights shared during the previous session, “Co-creative supply chains”, Chmielarz of JLR delved further into the human dimensions of digital transformation during the panel discussion. She emphasised that users often feel “overwhelmed by new systems and interfaces,” a challenge JLR is addressing through “Project Revive”.

Chmielarz reiterated the importance of fostering collaboration through tools like product lifecycle management platforms. Such integration, she explained, not only enhances decision-making but also positions logistics as a strategic contributor within JLR’s broader transformation.

Volkswagen’s Sommer reinforced the need for a robust master data strategy to ensure supply chain visibility. “Data consistency is essential, but we must also consider the end-to-end process,” he explained, advocating for clear ownership of data responsibilities across functions.

The panel also addressed digitalisation challenges in supplier and logistics provider collaboration. Real-time data sharing, while beneficial, must be balanced against practical limitations. “Sometimes, less is more. Controllers don’t need all the data; they need actionable insights,” said Chmielarz.

The session concluded with a call to action: embrace digitalisation as an integral part of logistics. “Digitisation is logistics,” Sommer stated, urging the industry to integrate IT and operational strategies fully.

4 December

JLR’s path to integrated supply chains

Paulina Chmielarz, digital and innovation director of industrial operations at JLR, outlined the company’s strides in breaking down silos and fostering enterprise-wide collaboration at the “Co-creative supply chains” session. Her presentation highlighted the critical role of fusion teams in bridging business and IT gaps, ensuring seamless integration and effective digitalisation.

“End-to-end digitalisation requires organisations to build cross-functional teams with a mix of technical and business expertise,” explained Chmielarz. She positioned these fusion teams as the linchpin of JLR’s transformation, facilitating collaboration across departments and translating technical solutions into tangible business value.

Watch: JLR’s Paulina Chmielarz on how JLR drives digital transformation

JLR’s progress in integrating product lifecycle management and enterprise resource planning systems serves as a case study. “We’ve achieved over 130 use cases with complete end-to-end bill of material integration,” she noted, adding that this has improved coordination between supply chain and engineering teams, with logistics integration set to follow.

Chmielarz also discussed the findings from “Project Revive,” a study designed to understand digital adoption within JLR. “Through a discovery phase involving hundreds of team members, we learned that leadership endorsement of digital tools is more impactful than training alone,” she revealed. The project focuses on improving user experience and addressing root causes of low adoption, ensuring digitalisation delivers its intended value.

The transformation extends to managing software changes in supply chains, a historically complex area. Chmielarz highlighted how a software bill of materials enables JLR to track and manage digital assets with the same efficiency as physical parts, eliminating phantom processes.

Concluding, she remarked on the critical interplay of people, processes and governance in sustaining JLR’s digital journey. “The machine is now complete, the machine is moving,” Chmielarz affirmed, underscoring the tangible results and continued innovation ahead.

4 December

A pragmatic vision for supply chain transparency

Volkswagen Group’s head of information process logistics, Thorsten Sommer, opened with a keynote that focused on supply chain transparency and the integration of data management with AI-driven solutions. Sommer emphasised execution over strategy, offering actionable insights to industry leaders.

“Transparency in the supply chain sounds simple,” Sommer remarked, “but challenges such as silo thinking, unharmonised processes and inconsistent data make it a complex goal.” He noted that transparency is not only essential for operational efficiency but is increasingly driven by regulatory demands, including the EU’s Deforestation Directive and evolving product passport requirements.

Sommer identified three core obstacles to transparency: organisational fear of exposing inefficiencies, a lack of data quality awareness and technical fragmentation caused by proprietary IT solutions. To address these, he advocated for breaking silo thinking and establishing a cultural shift towards data sharing, supported by centralised management. “Data management should be centralised wherever possible,” he said, stressing its role in creating unified standards and reducing redundant maintenance costs.

One of his key recommendations was to “start small and think big.” Sommer encouraged organisations to leverage existing data before pursuing expansive new datasets. “Harvest with what you have; each harvest yields seeds for the next,” he advised, highlighting the importance of balancing efforts between data collection (“sowing”) and application (“reaping”).

Sommer concluded, “Regulations are not obstacles but boosters for innovation – embrace them to fuel your data strategies.”

4 December

Driving transformation at ALSC Digital Strategies Europe day two

The second day of the Automotive Logistics & Supply Chain Digital Strategies Europe 2024 conference opened with a forward-looking exploration of how digitalisation and innovation are reshaping automotive logistics. In Ludwig’s welcome remarks, he underscored the significance of these trends: “Yesterday, we hit on quite a few topics around data strategy, around visibility, certainly around AI and advanced automation. Today, we’ll go deeper and challenge some areas in terms of vision versus reality.”

Day two’s agenda promises to address pivotal topics, including transparency within and across supply chains. “Over the next hour and a half, we are going to be looking in depth at some of the really strategic areas of digital transformation in terms of transparency – transparency across the supply chain, within companies, across different departments and cross functions,” noted Ludwig.

High-profile speakers from industry leaders, including Volkswagen, JLR and Brose Group are scheduled to share their strategies and tackle challenges in visibility, digital transformation and data strategy. One of the goals of today, according to Ludwig is to explore “what some of the challenges and blind spots are in enhancing this visibility.”

Attendees are encouraged to login to the app to explore the agenda and connect with other attendees, plus access event photos through Pica.

3 December

Catch the key moments from Day 1 in Munich! From diversity and talent forums to cutting-edge AI and robotics, we explored how innovation is transforming the automotive supply chain. Hear insights from BMW, CATL, JLR, and more, and discover what’s next in digital strategies.

Don’t miss the highlights and stay tuned for more updates from Day 2!

3rd December

After a day of insightful sessions and workshops on AI, digitalising supply chain, data security, sustainability and real-time discussion on future applications of digital tools from some of the industry’s experts, the delegates and speakers attended a networking dinner hosted by Automotive Logistics.

We will be back tomorrow for Day 2 of the conference with more insights from JLR, Volkswagen Group, Brose Group, Mercedes-Benz AG, Toyota Motor Europe, Bosch and many more. Stay tuned!

3rd December

Digital applications are only as good as the data on which they are based

After some workshop brainstorming on a range of subjects that included AI applications, supply chain mapping, data security in sustainability and building digital twins, delegates ALSC Digital Strategies Europe gathered to summarise their findings.

John Torres, lead data scientist at Mercedes-Benz, said there was no shortage of challenges in the sector that AI could help solve but even that took a better shared understanding of where the tool itself needed improvement. There needs to be more data of a better standard that is better structured and better governed, according to Torres.

One of the important things to consider when applying AI tools in the automotive supply chain is the value they have for a company’s business. “It’s super important that we are not using AI just for the sake of it but that we actually understand the value behind it,” said Torres. “Is it actually solving a problem or is it there just because of the hype?”

Managing expectations and having sponsorship to develop AI tools over time is also important, something Mercedes-Benz has achieved in starting small and being able to work up through different iterations of its forecasting system. Data governance is important and a company needs to be clear on who is responsible for that data and how it is shared to avoid costly and time-wasting duplication. Who it is shared with is also important and that needs to be democratic, involving those responsible for the direction of the business. “If you can have a clear governance framework you make sure that your data is created once, cleaned once and then consumed by everyone.”

Data management is also crucial to supply chain mapping and JLR’s director of supply chain digital and innovation, Simon Inskip, summarised his team’s workshop in three main themes.

Data needs to be shared in a way that everyone is comfortable with and that again relies on a shared understanding, trust and a degree of impartiality. Inskip summed up the basic approach: “When I ask you for a piece of data, do you know what I mean? Are you willing to share it? And if you do share it, do I trust that you’ve given me accurate data?” He said Catena-X can hopefully provide the trust and impartiality needed.

With reliable data gathered it is also important to know what technology can make best use of it. “In JLR alone we’ve mapped 180,000 points of our supply chain and if I want to do something meaningful with that, I need something more than a couple of spreadsheets,” he said. Looking at different technologies for the retrieval and application of gathered data is important, according to Inskip’s workshop group.

The impact of the technology on businesses depends on alignment on goals, methods and standards, and that required actually doing some meaningful with the sharing of data on a specific but large enough scale so that the learning from it can be shared for everyone’s benefit, according to Inskip. From there it can refined and scaled.

Infineon’s director of supply chain management, Soroush Nakhaie, led a workshop on how digital tools could help drive sustainability in the supply chain but found that data security was actually holding that back. Decarbonising the supply chain requires cooperation but sharing data on carbon expenditure remains a big hurdle. Sustainability is being driven by regulation, which affects the obligation to disclose information. “Is it just an annual report on CO2 or is it really the obligation that the whole value chain exchanges information with each other and we know what CO2 a product from cradle to grave is actually creating?” questioned Nakhaie.

Nakhaie also pointed to the insight that can be gained and implemented from the workforce and how important simple measures such as cutting large megabyte email attachments can actually mean for reducing electricity expenditure and cutting CO2.

Finally, Dr Tobias Engel, professor of supply chain management at the University of Applied Sciences, led a workshop on the value of digital twin technology in the supply chain. He said that digital twin technology is part of the industrial metaverse and its functionality was in being able to plan the supply chain based on what can be simulated and then control and monitor the processes during operations.

Digital twins enable collaboration regardless of physical space and like a multiplayer game it is possible for an OEM to bring a supplier or logistics provider into the same digital space to look at a particular problem. Engel took the example of transport disruption. “You can see [together] if this is a ship or an airplane, and what is going on, is it a hurricane, is it a tornado? If it is a traffic jam, have you lost a container? This is the capability of digital twins and the industrial metaverse – you’re able to manage the real world,” he said.

Good master data and central storage are important for a company, as is having control of one’s own data. Engel said that with a digital twin of the supply chain a company can secure material supply, foresee any environmental issues, measure transport emissions and see exactly where a product is in the supply chain, all guaranteeing better customer service. “There are a lot of options with the digital twin and we’re only at the beginning of the journey,” said Engel.

3 December

Networking break and exhibition visit

After a couple of insightful presentations and panel sessions, we will be breaking onto our second coffee break for further networking and an exhibition hub visit where suppliers have set up stalls for delegates to experience! We will be back with a set of workshops on AI in supply chain and logistics, Tier-N supply chain, digitalisation in sustainability goals and digital supply chain twins with Mercedes-Benz AG, JLR, Autoliv, Infineon Technologies, University of Applied Sciences and University of Applied Sciences Neu-Ulm.

We will end the conference with a networking drinks reception with fellow attendees as we look forward to day two.

3 December

Dancing to the same tune in the sharing of supply chain data

Following close on the heels of today’s AI discussion, Frank Göller, took to the stage to outline the progress of the Catena-X data-sharing platform. Göller is head of strategy and portfolio management, digitalisation production/logistics at Audi. He is also vice-president of internationalisation at Catena-X and there has been significant progress in internationalisation since the data platform was established in Germany in 2021.

Companies in Europe, the US, China and Japan now have an understanding of what Catena-X can do to make manufacturing logistics processes more efficient and resilient through shared global standards for cross-border data exchange. That is no small feat and Göller admitted it is “a complex beast to understand” but making it a reality that lives as an organisation of data across the supply chain is even more tricky. The secret to a more efficient automotive supply chain relies on more small-to-medium-sized companies directly participating in it. Catena-X currently has 192 participating companies and over 6,000 community members worldwide but it has a target of getting 1,000 companies directly involved in data exchange by the end of next year.

That is important when considering how important supply chain transparency is in quicky identifying potential disruption to inbound parts and material flow, which Catena-X is designed to do. “We all know the semiconductor crisis, and we all know the hiccups with missing parts in the supply chain flow to production,” said Göller. “Catena-X is addressing this.”

However, shared data is also important for addressing future regulatory requirements, such as product carbon footprint tracking, battery passports, circular economy regulations and textiles. “It’s not only automotive… if you’re producing products you should think about how to fulfil the requirements of a product passport,” said Göller, adding that Catena-X was a ‘snowplough’ clearing the road ahead for other industries. “We have made an analysis that up to one billion data points have to be collected and reported in the year 2030 to fulfil forthcoming regulatory requirements.”

Göller said that Catena-X was set up to make the supply chain more efficient and effective by driving faster feedback loops between OEMs and suppliers to the tier-n level and smoothing the delivery of products to assembly. “We know that if we can react quicker, we can solve problems and be much faster in the throughput time,” he said. That relies on collaboration on the exchange of data and an open sharing of relevant capacity and demand data to improve the lean flow of parts.

Catana-X is not simply a data lake or a cloud, according to Göller, it is a data space that is based on collaboration, trusted services and interaction between the partners from across the supply chain; and it promises to cut costs. Those can be manufacturing and logistic savings by avoiding stoppages or hiccups in ramp up curves. It can herald cost saving by fulfilling regulatory requirements and avoiding fines for not doing so. And it can bring savings accrued through joint services, such as those related to master services with suppliers and using the golden record everyone wants to have.

“We can exchange data and there is no kind of hierarchy,” said Göller. “We are dancing together and choosing the music together.”

3 December

The role of control towers in digitalising the supply chain

Alex Rotenberg, vice-president, industry practices at Kinaxis joins a panel discussion with Seat’s Lerma and Díaz, and BMW’s Richter, to discuss the role of control towers and human-AI collaboration.

The discussion is exploring the evolution of control towers, which serve as centralised platforms for managing supply chain data and workflows. Rotenberg describes a journey from “self-healing” supply chains that clean up data to “self-learning” systems that predict and resolve disruptions autonomously.

Seat’s control tower strategy aligns closely with this model, incorporating generative AI to simulate scenarios and enable real-time decision-making across a growing network of suppliers and plants.

While the panel celebrates AI’s transformative power, they also understand its limitations. Richter cautions that autonomous robots, factories and vehicles are not yet fully realised, and organisational challenges remain a significant barrier to broader adoption.

The consensus is clear: AI is a tool to empower, not replace, human intelligence. “AI creates new jobs that focus on maintaining, training, and optimising these technologies, enabling us to combine human expertise with machine efficiency,” Richter says.

3 December

AI-powered automation in Seat’s supply chain

Alexandre Lerma, manager of logistics, customer driven supply chain, Seat and Jorge Miguel Corral Díaz, senior IT specialist, AI, data & hyperautomation, Seat have taken to the stage to discuss the role AI-powered automation plays at the OEM, integrating data-driven decision-making and generative AI into operational processes.

Seat’s digitalisation journey began with the creation of a unified data lake, using Snowflake on Azure, to consolidate siloed data across departments. This has enabled the company to enhance collaboration through federated working models, combining IT expertise with departmental data stewardship. Their low-code and no-code solutions, built on platforms such as Power BI and Vortex AI, empower employees to create efficient workflows and address logistical challenges.

Vortex AI, Seat’s proprietary generative AI tool, offers various tailored solutions. Unlike off-the-shelf tools, Vortex AI ensures data privacy and compliance with European regulations like the AI and Data Acts, according to Lerma and Díaz.

The strategy is underpinned by robust employee training, with learning paths designed to upskill staff in tools, data stewardship, and low-code development.

3rd December

AI and robotics transform supply chain at BMW

BMW’s head of next generation robotics, Carolin Richter, presents the company’s cutting-edge advancements in AI-powered automation and robotics. Central to her keynote is BMW’s collaboration with Figure AI, a robotics company advancing humanoid applications for industrial use.

Richter highlights BMW’s ambition to develop “intelligent robots” capable of performing manual tasks previously deemed too complex or costly to automate. She underscores the potential for humanoid robots to revolutionise labour-intensive processes, addressing workforce shortages in BMW’s production network.

The collaboration with Figure AI has already yielded significant milestones. Robots trained in Figure’s San Francisco lab are tackling tasks like metal part insertion at BMW’s Spartanburg plant. Initial trials showcased robots using AI to autonomously identify, manipulate and integrate components into production lines, offering flexibility and scalability.

Richter reveals plans to deploy these humanoids in active production settings by early 2025, overcoming challenges in safety, IT integration, and European AI regulatory compliance.

While logistics applications are still in early development, the potential to automate complex material handling and last-mile operations could bridge critical gaps in supply chain efficiency.

3 December

Networking break

We are breaking for our first coffee break of the day where delegates and speakers will get to network and discuss the ongoing trends in digital strategies, supply chain and digitalisation.

We will be back for a session on AI-powered automation in supply chain and logistics with Carolin Richter, head of next-generation robotics at BMW Group, Alexandre Lerma, manager of logistics, customer-driven supply chain at SEAT, Jorge Miguel Corral Díaz, senior IT specialist – AI, data & hyper-automation at SEAT and Alex Rotenberg, VP, industry practices at Kinaxis.

Next, Frank Göller, head of strategy, portfolio management digitalisation production/logistics, AUDI and VP internationalisation at Catena-X e.V. will present a keynote from an exponent on the internationalisation of Catena-X, on how the organisation is developing partnerships, just in North America with AIAG, but also in China and Japan.

Stay tuned and come back for exclusive insights from the event.

3 December

Diversity as a catalyst for automotive supply chain innovation

Now, we are joined by a panel discussing digital supply chain leaders and how a diversity of skills and talent can help accelerate a digital, more competitive future in Europe.

The panel (Juliana Raidt, head of data privacy and information security at Bosch; Harry Kwakye Davies, a senior global supply manager in the automotive industry; Trre Wong, senior manager, global supply chain digitalisation at Kautex Textron; and Saba Azizi, overseas service network & development manager at CATL) are sharing their personal journeys and actionable strategies to foster inclusion and equity in the automotive sector.

Retention strategies remain a focus for the panel. Davies says there needs to be a shift from mentorship to sponsorship, ensuring employees from underrepresented groups have the resources and visibility needed to thrive.

CATL’s Azizi says the power of visible diversity in leadership in important. “Young people lose motivation if they don’t see representation at the top,” she says, urging companies to focus on creating leadership pipelines for diverse talent.

Managing global teams with varying cultural norms poses challenges. Bosch’s Raidt highlights the importance of communication: “Leaders must create safe spaces where every team member feels valued and heard, regardless of background or seniority.”

Wong adds that digitial strategies can be used to improve diversity, saying that inclusivity extends to respecting different working styles and integrating digital tools to bridge gaps in digital literacy.

3 December

Welcome to Automotive Logistics & Supply Chain Digital Strategies Europe 2024!

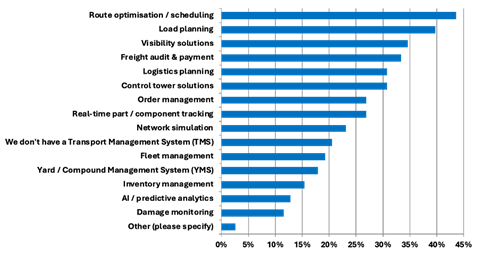

We’re opening the conference in Munich with Christopher Ludwig, chief content officer, Automotive Logistics discussing trends in automotive supply chain systems and software.

Ludwig shared insights from the Automotive Logistics Software & Systems Survey, which he said highlights clear intent in the industry to invest in interoperability, digital strategy and AI and analytics.

“What we also found is that AI and predictive analytics is still a developing area,” he said. “A relatively low percentage actually are using it in any specific way right now, but the intent is very strong. So it’s a big opportunity area as we make these further investments.”

Download the full Automotive Logistics Software & Systems Survey report for free

2 December

ALSC Digital Strategies Europe is only a day away!

Ahead of the event kicking off, we spoke to Aleksej Kruekov, general manager of overseas service, EMEA at CATL about the challenges in digitalising automotive logistics, including lack of truck interoperability, geopolitical restrictions, and operational silos that reduce efficiency, and how CATL is addressing these issues through transparency and investments in new technologies.

Kruekov will be taking to the stage on the second day of the conference (4th December) to discuss how collaboration can drive supply chain digitalisation.

For the full lineup of speakers on the agenda, visit here!

29 November

Paulina Chmielarz, digital and innovation director of Industrial Operations at JLR will be taking to the stage at ALSC Digital Strategies Europe next week to discuss how the carmaker’s ongoing transformation will enhance transparency and integrated planning, including creating master datasets that ensure supply chain and logistics stakeholders can interact with and influence key processes, including engineering, materials and vehicle launch.

She took to the Red Sofa at last year’s event to discuss ensuring the OEM’s teams are fully aligned with the same data sets.

Watch the full Red Sofa video here!

28 November

Frank Göller, head of digital strategy and portfolio management for production and logistics at Audi, and head of internationalisation at Catena-X, will be taking to the stage next week in Munich to discuss the future of data standards across boundaries and ensuring carmakers and suppliers can fully digitise their value chains.

Göller spoke to Automotive Logistics recently about how developing global standards for cross-border data exchange will make manufacturing logistics processes more efficient and resilient. He said that some companies are hesitant to share data, but that regulatory requirements coming into effect over the next three to five years could help ease concerns.

“Our analysis shows that over one billion data points have to be tracked, recorded and monitored for regulatory requirements up to the year 2030,” he said. “We have checked the different regulations in US, in China, in Japan – all around the world – and that means a really high amount of data tracking requirements by law.”

28 November

Welcome to the Automotive Logistics & Digital Strategies Europe 2024 countdown blog!

Before we land in Munich, Germany next week, we’ll be posting news and features related to the expert speakers who will take to the stage, so follow along here to ensure you don’t miss any insights!

From 3-4 December, we’ll be hearing from a range of speakers from the likes of BMW, VW, Catena-X and more.

Click here to view the full agenda!

Experts from VW, Audi, BMW, Catena-X, Toyota, JLR, Infineon, CATL, Mercedes-Benz, SEAT, Daimler Truck and more gathered on stage at this year’s Automotive Logistics & Supply Chain Digital Strategies Europe, which took place 3-4 December in Munich, Germany.

The speakers discussed how to form a more co-creative, resilient and sustainable supply chain, providing insights into using the latest digital advancements to tackle uncertainty, volatility and cost pressures. Follow our recap blog to get insights, news and Red Sofa video interviews from the event.

Topics

- AI & Predictive Analytics

- ALSC Digital Strategies Europe 24

- Cross-Border Logistics

- Cybersecurity

- Data Integration & Interoperability

- Digitalisation

- Electric Vehicles

- Europe

- Features

- features

- Lean Logistics

- Lean Transformation

- Logistics service provider

- Nearshoring

- OEMs

- People

- Policy and regulation

- Shipping

- Supplier Diversification

- Suppliers

- Supply Chain Planning

- Sustainability

- Sustainable Supply Chain Design

- Technology service providers

- Track-and-trace

- Trade & Customs

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)

No comments yet