At its Factory Booster Day, chief manufacturing officer Arnaud Deboeuf and process engineering lead Jean-Christophe Marchal reveal AI projects with partners for digital twins and retrofitting equipment, including for plant logistics.

With ambitions for a dramatic reduction in manufacturing costs by the end of this decade to increase competitiveness and profitability, Stellantis is putting practical digital innovations at the heart of its plans to improve productivity across plants and operations, including a strong focus on automating and digitalising in-plant logistics to create leaner processes.

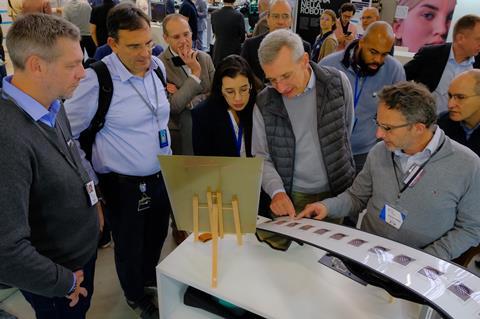

Speaking to journalists ahead of its annual innovation event, Factory Booster Day, held on September 18 at the carmaker’s Mirafiori Complex in Turin, Italy, Stellantis manufacturing leadership emphasised the importance of incremental but scalable solutions implemented together with suppliers and innovators.

“It is not about innovation for innovation’s sake; it’s about solving the problems of tomorrow,” said Stellantis chief manufacturing officer Arnaud Deboeuf. “We are focused on reducing manufacturing costs by 40% [by 2030], achieving carbon net zero, and becoming number one in customer experience.”

Deboeuf introduced partners with whom Stellantis is rolling out solutions across global manufacturing processes – and had also participated in recent Factory Booster Days. These included a cloud-based planning system from Autodesk that will play an important role in creating digital twins, and an AI-driven vision system from French startup Inbolt that helps existing robots track parts in real time.

An innovation with strong potential to improve logistics operations was a low-cost autonomous mobile robot (AMR) solution from Norwegian startup wheel.me, which automates existing material-handling equipment.

This year’s Factory Booster Day featured more than 60 partners and 93 innovations, including from startups, established suppliers and universities. Over the past three years, more than 300 proposals at the annual event have been considered by the Stellantis manufacturing team. According to Deboeuf, implementing such innovations, along with continuous improvement and lean processes, has reduced transformation costs by 11%, energy consumption by 23%, and quality issues by 40% since 2021. “Leveraging the latest technologies, especially AI, is a significant lever to achieve the level of excellence we are aiming for,” he said.

This focus on innovation comes at a time when Stellantis operations are under strong cost pressure. As part of the Stellantis Dare Forward 2030 strategic plan, the carmaker has set a target of reducing production costs by 40%, including deploying automation, digital solutions, and artificial intelligence. The company recently announced a significant drop in profits, and CEO Carlos Tavares has emphasised the need for efficiency improvements in producing electric vehicles, and as the carmaker faces strong competition, including from Chinese OEMs.

“We are looking for solutions which the plant managers can manage by themselves. We don’t want process engineering teams to spend time adapting or modifying the path for equipment or containers.” -Jean-Christophe Marchal, Stellantis

Reinventing the wheel for plant logistics

According to Jean-Christophe Marchal, senior vice-president of vehicle process engineering, plant and internal logistics are areas where Stellantis aims to accelerate automation and digitalisation, particularly in the movement of containers and packaging between storage areas, supermarkets, and the line side.

“We want to have this transportation done in an efficient manner and to be able to design, implement, and manage different sizes of containers, not just a single standard,” he said.

He highlighted wheel.me as a flexible, low-cost solution for the autonomous transport of parts and packages within plants without significant infrastructure changes. The wheels replace standard casters on existing dollies, automating the movement of parts or commodities within factories.

“Our autonomous robotic wheel can be deployed in existing infrastructures, allowing plants to move containers and packages efficiently,” said wheel.me COO and Deputy CEO Pål M. Rødseth. “We like to say that we’ve ‘reinvented the wheel.’”

The system is already operational at Stellantis’ Sterling Heights plant in Michigan, with discussions ongoing for a wider rollout.

“Compared to what you see normally in the plant, we can convert existing trailers and equipment into autonomous vehicles without major changes, which was exactly what we needed,” added Deboeuf. “It’s a perfect fit for our compact plants where space is limited.”

Solutions with minimal change and downtime

The wheel.me solution follows a pattern of digital solutions that retrofit equipment and allow for fast, simple implementation while delivering strong results in manufacturing and logistics. Inbolt’s AI-powered robot guidance system, for example, can be installed on existing industrial robots, using cameras and real-time data processing to enable robots to make on-the-spot decisions, mimicking human adaptability on moving assembly lines.

“Our vision system allows robots to track moving parts in real-time, meaning we don’t have to retrofit entire production lines for automation,” said Inbolt co-founder Albane Dersy. The technology has been deployed in five Stellantis plants, with 25 more installations planned by the end of the year.

According to Marchal, Stellantis is looking for solutions that require minimal adaptation costs and downtime. “We are looking for solutions which the plant managers love, want to implement, and can manage by themselves,” he said. “We don’t want process engineering teams to spend time adapting or modifying the path for equipment or containers, and we want to avoid digging or building anything on the shop floor.”

That doesn’t mean the carmaker isn’t pursuing ambitious projects that span multiple functions. Stellantis is also leveraging Autodesk’s Construction Cloud to enhance the design and planning phases of new production lines and facilities, aiming to speed up development time and avoid errors or engineering changes that negatively impact production and logistics costs.

“What we’ve rolled out with Stellantis is a digital platform that allows different stakeholders—engineers, suppliers, and plant teams—to collaborate in real time,” said Dr. Alexander Stern, manufacturing strategy lead from Autodesk. “This reduces digital waste and accelerates the validation process.”

Stellantis has already used the technology at its Windsor assembly plant, where it was instrumental in reducing setup time and improving overall design quality. According to Marchal, Stellantis is in the process of digitally scanning all its plants, starting with those that have major vehicle projects planned. (Read more on the Stellantis strategy for digital factory twins and the use of AI in production at Automotive Manufacturing Solutions, a sister title to Automotive Logistics.)

Earlier this year, Stellantis Chief Purchasing and Supply Chain Officer Maxime Picat told Automotive Logistics that the carmaker was focusing on digitalisation to better anticipate changes and risks in the supply chain, as well as better integration of supply chain and purchasing engineering teams to further reduce logistics costs.

Deboeuf also revealed that Stellantis is working on applications using generative AI, including for maintenance operations.

Despite the challenges and pressure to reduce costs, Deboeuf emphasized that these digital solutions were implemented in close collaboration with both partners and employees in production and logistics. “We are not imposing technical solutions from the top down. These innovations answer real problems raised by our plants,” Deboeuf said. “Our goal is to implement solutions quickly and effectively to drive our manufacturing into the future.”

Supply chain and logistics leaders will discuss digitalisation innovation and opportunities in artificial intelligence, transparency, automation and more at Automotive Logistics & Supply Chain Digital Strategies Europe in Munich this December. Join speakers and attendees from Toyota, BMW, SEAT, AUDI, Bosch, Brose and more. Find and more and register here

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)

No comments yet