Can the UK supply chain keep up with a 2030 ban on new ICE vehicle sales?

By Daniel Harrison2020-11-20T14:31:00

The UK government has announced it is bringing forward its plans to phase out the sale of new cars and vans powered by internal combustion engines. Daniel Harrison, automotive analyst at Ultima Media, examines how realistic that is and whether supply chains are ready to produce enough electric vehicles and batteries.

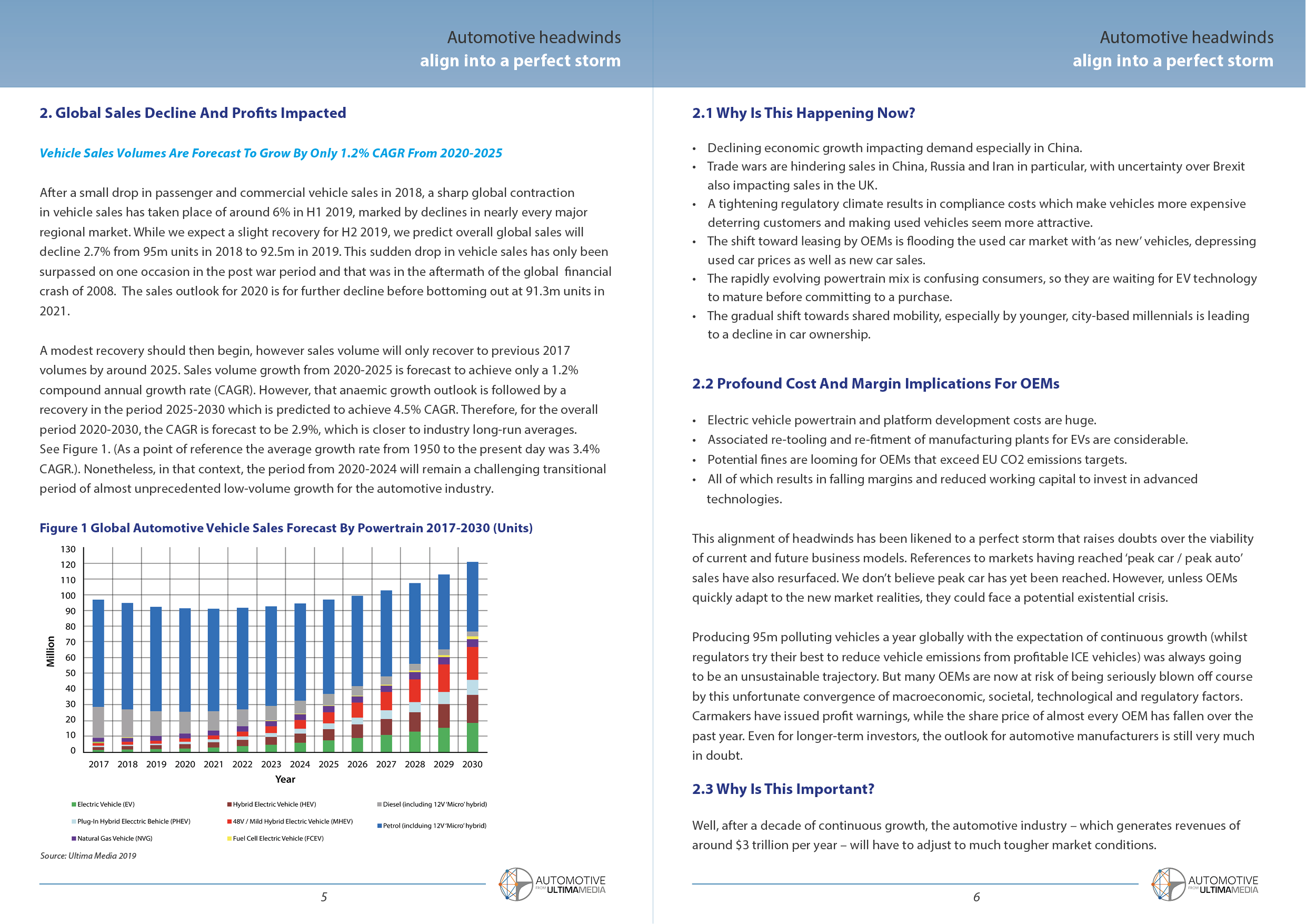

Given that it typically takes 5-7 years to develop a vehicle and bring it to market, this target will be fewer than two product cycles away for many OEMs. It will be enormously challenging for an industry already reeling from the Covid crisis, the costs of meeting stringent CO2 emission targets and the imminent and still fully unknown impacts of Brexit. It will also require huge investment and efforts to mobilise the supply chain to produce batteries and other components to support EV manufacturing and service.

Although EV sales have been rising fast, even in a market seriously disrupted by the pandemic, pure electric vehicles currently account for just over 5% of new vehicle sales in the UK, while hybrids and plug-in hybrid electric vehicles (PHEV) are just over 10% – which means around 85% of current vehicle sales would be affected by the ban. Despite huge investment in EV technology, so much of the automotive industry, including its technology and engineering base, its supply chains and service still revolve around ICE powertrains. However, in just 9 years’ time, all new vehicle production will have to be fully electric or strongly hybridised, with a supply base and infrastructure in place to support it.

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)