From the beginning of June this year DP World will be providing an intermodal rail service for containerised car shipments between Mexico, the US and Canada. The port terminal and inland logistics provider is using 16-metre (53ft) containers with R-Rak cassette systems in answer to the ro-ro and multilevel rail-capacity shortage for vehicle shipments in North America.

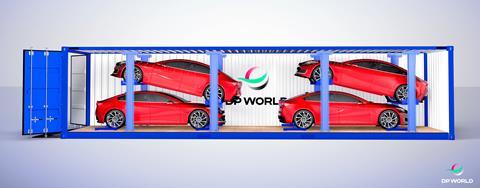

The 16-metre containers, which are common for general freight shipments in North America, can accommodate up to six passenger vehicles on special racking systems, compared to the four maximum that can be shipped in a standard 12.2m (40ft) container, which DP World said enhances efficiency and reduces costs for OEM customers. Four larger SUV-sized cars can be shipped in the containers. DP World said it is the only logistics company currently providing the intermodal 53ft container solution for finished vehicles.

Door to door transits range from 8-14 days, depending on the route, according to DP World. Working with three Class 1 rail companies in North America, DP World is moving the vehicles across the US-Mexican border at Piedras Negras across the Union Pacific International Railway Bridge. The commencement of the service follows initial volume shipments in the first quarter of 2024 for a major OEM.

GM, Nissan and Volkswagen are the top three carmakers exporting vehicles from production sites in Mexico to the US and Canada.

Containerised vehicle service

DP World acquired CFR Rinkens in October last year to bolster the development of its services for containerised vehicle shipments. Christoph Seitz, former CEO and cofounder of CFR Rinkens, and now global vice president for finished vehicles at DP World, said: “Our extensive experience shipping cars in containers worldwide, our large racking fleet, and our expert teams and hyper focus on quality and service, have enabled DP World to provide this unique solution in a challenging environment.”

Seitz went on to say that initial volume shipments in 2024 are proof of concept that the 53ft intermodal solution is a viable alternative during times when traditional capacity is tight and that is why it is offering the programme to the wider market. He said the use of the standard 53ft containers was a good option for vehicle shipments because their length and additional width make it easier to load and unload the vehicles. Seitz forecasts that the service could move 30,000 vehicles in containers by rail this year. He said that since the beginning of 2024, the company has already transported over 5,000 cars across the Mexico-US border for US and Japan-based OEMs with manufacturing in Mexico.

There is currently no significant return service for finished vehicles to Mexico but because the containers are used for a wide variety of freight once the vehicle racking cassettes are taken out, they can carry other freight across the border, including automotive parts. DP World is putting 60 collapsible return racks into a container around once a week from locations in LA, Chicago and Detroit which are returned to Mexico.

Intermodal management

The service will load finished vehicles into containers directly at the factories in Mexico or use car haulers to shuttle them to designated yards that can load the vehicles into containers close to the manufacturing hubs. The containers are then trucked to intermodal rail ramps and moved by rail to destinations including Los Angeles, Chicago, Detroit and Toronto. At destination, the containers are trucked from the rail ramp to designated yards where the cars are unloaded and trucked to the dealerships. DP World is coordinating with first- and last-mile car haulers for delivery from the plants to its origin stuffing yards and for onward road shipments of the vehicles to the dealerships in the US.

Finished vehicle trade in North America at a time of significant manufacturing growth in Mexico is bolstered by the 2020 United States-Mexico-Canada Agreement (USMCA). In 2023, Mexico surpassed China to become the US’ top trading partner. At the same time, Chinese OEM manufacturing investment in Mexico has increased.

Christoph Seitz will be speaking at the opening session of next week’s Finished Vehicle Logistics North America conference in California, which is focused on reimagining the finished vehicle logistics network to enhance performance in the face of capacity challenges. He will be joined by Ford’s Paul Roosen, vehicle logistics planning manager for North American vehicle logistics, Lisa Kline, vice-president of vehicle planning and logistics at Subaru of America, and Sean Baltazar, senior vice-president of sales at RPM.

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)

No comments yet