JLR and its innovation partner Plug and Play have launched a second Innovation Challenge aimed at innovators who can develop ways of enhancing the accuracy of traceability, risk mapping and visibility across the full length of the supply chain.

JLR has launched a second Innovation Challenge that invites start-ups, academics and other innovators to create a future-focused supply chain mapping technology and win an opportunity to develop a proof of concept with JLR’s experts and scale the solution to commercial application. The deadline for applications is April 25 this year.

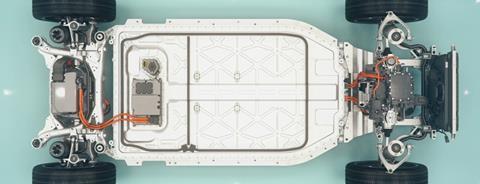

JLR said that since the disruption of the Covid pandemic it has been streamlining its supply chains and working on partnerships with suppliers to improve planning and parts visibility, as well as safeguarding JLR from disruption. It is currently looking for supply chain resilience as it develops the next generation of electric vehicles (EVs) and the global supply network to support that.

JLR Innovation Challenge applications – key dates

• March 19, 2025: Applications open

• April 25, 2025: Applications close

• July 3, 2025: Pitch Day event

For more information and to apply, visit JLR Innovation Challenge

For this year’s Innovation Challenge, which is held in collaboration with innovation platform Plug and Play, applicants are being tasked with developing ways of enhancing the accuracy of supply chain traceability, risk mapping and visibility, from tier one parts and components suppliers down to the tier-n material suppliers, including those extracting raw materials for the EV battery. The solutions can include AI, big data and predictive analytics.

“The future of supply chains is autonomous, intelligent and data driven,” said Paulina Chmielarz, digital and innovation director, Industrial Operations at JLR. “At JLR, we’re harnessing the power of AI, machine learning, and real-time analytics to unlock unprecedented visibility and resilience.”

Chmielarz said that JLR is calling on innovators, start-ups and tech pioneers to join the company in building the next generation of automated supply chains and redefining what is possible.

Environmental and social governance are priorities for the EV supply chain and JLR said it is developing supply chain transparency to help eradicate forced labour, and illegal deforestation and mining.

JLR opened a UK innovation hub in partnership with Plug and Play in 2022 as part of its Open Innovation strategy, designed to accelerate next‑generation technology and sustainability. In June last year it held a Sustainability Innovation Challenge. The innovation drive feeds into JLR’s Reimagine strategy to become a carbon net zero business by 2039. The company is investing £15 billion ($19.4 billion) in its industrial footprint, vehicle programmes and talent, and in autonomous, AI and digital technologies.

Previous Innovation Day winners include:

1st Place: Genomines uses genetically enhanced plants to mine metals central to electrification such as nickel from the soil, aiming to become the first carbon-negative mining group

2nd Place: Circuli-ion specialises in the automated disassembly and upcycling of battery packs

3rd Place: aircela develops direct air capture technology to pull carbon dioxide from the atmosphere and convert this into a carbon-neutral fuel.

In November last year JLR announced a new seat foam, developed with fabric and seat suppliers Dow and Adient, made with closed-loop recycled polyurethane foam. JLR said it was the first time closed-loop seat foam content has been successfully used in automotive production.

In terms of vehicle logistics, JLR announced in January that it had joined UECC’s Sail for Change fuel switch initiative for the maritime delivery of finished vehicles, which offers the option to switch to biofuel for short-sea shipments.

No comments yet