The automotive industry’s transition to the production of battery electric vehicles (BEVs) is progressing under the banner of cleaner transport and more sustainable manufacturing. Established carmakers and start-ups are establishing BEV assembly plants with adjacent gigafactories in various parts of the world, driven by a strategy of greater localisation.

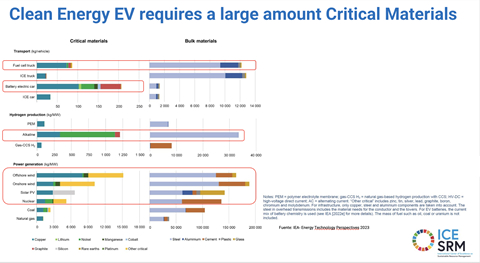

The use of BEVs is certainly part of the solution to pollution and emissions reduction, but the sourcing, mining and processing of the critical minerals on which carmakers depend for their lithium-ion batteries involve many environmental and social impacts. Added to which, the efforts to generate power from renewable sources such as solar and wind to power the factories, and the powergrid required to support electric transport, is itself reliant on the mining of critical minerals for solar panels and wind turbines.

At last week’s Automotive Logistics and Supply Chain Mexico conference, Ulises Neri Flores, vice-chair of the Expert Group of Sustainable Resource Management at the United Nations, outlined the main considerations that automotive companies had to make in assessing the impact their BEV production can have on the environment and on the communities present in the key critical mineral-producing countries around the world.

Climate change and social action

According to Neri, more companies are now focusing on the environment and looking at renewable energy and carbon emissions as part of their environmental, social and governance (ESG) discourse. That is increasingly bringing in wider supply chain considerations and efforts to reduce emissions in transport. Reducing emissions is the new rule of business but Neri said it was important to understand there are different options to reduce emissions, not only through renewable energy. There are other energy reduction actions and it is important to look for new technologies and strategies to make these reductions.

There is also a need for focus on the social and governance aspects of any ESG directives, including labour, health and security, as well as data and privacy security, and diversity and inclusion of the workforce. That is about understanding local community concerns and priorities and working together in collaboration to further sustainability beyond climate change, said Neri.

“More companies are making efforts and implementing different actions aimed at diversity and inclusion, transparency and responsibility, ethics, and anticorruption,” said Neri. “Which of these are properly feasible and applicable in your company depends on your geography, the size of your company [and] the place in which you are doing your business.”

A carmaker’s ESG claims have to be conversant with the sustainability development goals (SDG) drawn up by communities, local governments and international agencies. Carmakers and battery producers need to identify what are the main contributions they can make that align their ESG directives with the particular SDGs of a community.

More robust sustainability practices that properly consider the goals of the sourcing location will demonstrate better operational performance for the company carrying them out consistently which can translate into a positive influence on investment performance.

Neri said that when investors and asset owners replace the question ‘how much return?’ with ‘how much sustainable return?’ then they have evolved from a stockholder into a stakeholder.

UN standards

To help with this the UN has developed standards and tools developed by the UN can help vehicle and battery makers identify which activities involved in their production and which elements of their ESG goals coordinate with local SDGs and are more feasible to reinforce, according to Neri.

“There are standards and methodologies to identify the main SDGs,” said Neri. “The UN now offers different standards and methodologies for the different industries to identify properly which SDGs are more feasible to implement and reinforce in your industry.”

He added that what is very important to avoid is marginal or fragmented interpretations based on a random selection of the sustainable development goals established in a particular area. Applying consistent and complete standards and methodologies will enable a company to demonstrate the proper activities that are informing its sustainability efforts.

“Otherwise you are going to make diffuse or fragmented efforts with a lack of indicators or qualification,” said Neri.

Critical mineral mining

Mining activity for critical minerals used in EV batteries is one of the main parts of the automotive supply that has environmental and social implications. Mining and processing those minerals impacts the climate in terms of pollution, land use, water management and waste in different ways according to the mineral sourced. Cobalt, for instance, has more emissions including CO2 produced in its processing. While lithium does not have as much impact in terms of emissions the mining activities of lithium are located in areas of the world where there is water high-water stress and scarcity.

There are also many social implications, including health and safety and human rights. Neri said that Latin America had more conflicts in terms of mining exploitation than anywhere else around the world. With this in mind, companies have to ask what activities are the governments carrying out with the communities and industry to reduce the risk that they are using minerals in the supply chain sourced from zones of conflict and exploitation.

“[There needs to be] proper communication between governments, industry, suppliers and consumers to understand the issue and reduce the risk of conflict,” said Neri, adding that conflicts increase the risk in the supply chain and it is important to collaborate with government and community to ensure the supply of materials is maintained on ethical grounds.

“Coordination, communication and dialogue are very important,” concluded Neri. “The most challenging part for stakeholders is trying to understand who is the responsible party for activities in the energy and mining sectors. There are different ministries, regulators, universities, local governments and suppliers. It is a big group and complex to integrate but communication is a key element in defining a positive supply chain and positive logistics activities in [the automotive] industry.”

![Global[1]](https://d3n5uof8vony13.cloudfront.net/Pictures/web/a/d/s/global1_726550.svgz)

No comments yet